3,000 shafts stocked… Inside the Callaway tour truck

Last updated:

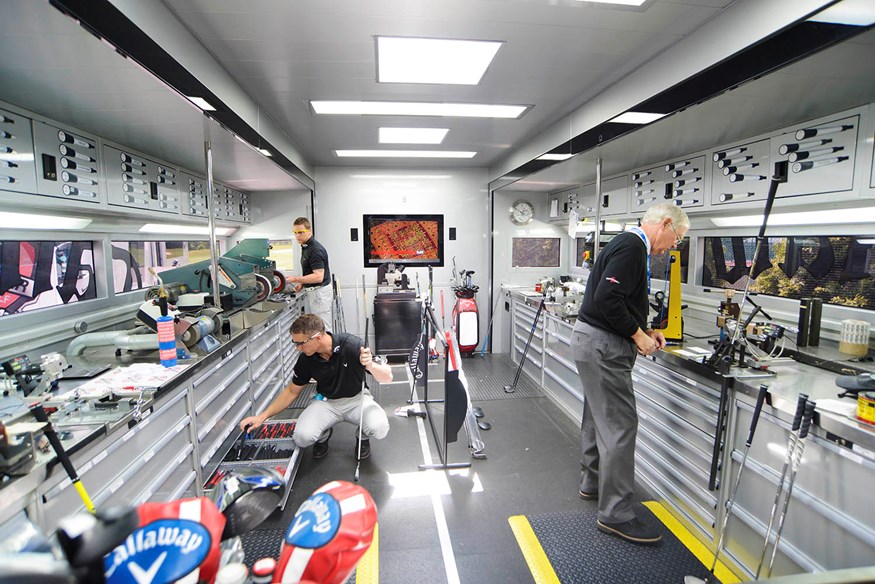

It may not seem the most glamorous job in the world, driving a 34.5-tonne truck and racking up thousands of miles every month.

But Paul Monks travels to 22 European Tour events every year, taking in some amazing locations and rubbing shoulders with Major champions.

The truck is often parked out of sight, normally adjacent to the driving range, but it’s constantly rammed during the practice rounds.

Players and caddies are always popping in with different requests, but what exactly goes on behind closed doors?

Monks reveals all…

1: Gripping station

On average, we do 50 to 60 re-grips per day at a tournament. That includes building new clubs as well.

We have around 25 guys competing on Tour and we have our own cloud-based website to look up the club specs for every player.

2: Grinding machine

One of the belts is really coarse and removes a lot of material, while the other one acts as a polishing tool. We also have two buffer wheels which smooth the finish on the sole of every club.

3: Belt sander

There are two sand belts which we use to prepare the tips of the shafts and maximise the stability of the bond inside the head.

We then measure the shafts using two rulers and mark how to trim them before using the cutting disc.

4: Ferrule machine

Before cutting or gripping a shaft we always trim the ferrule – the rubber piece covering where the shaft enters the hosel – on every club to ensure it blends into the shaft and you aren’t left with a chef’s hat.

5: Loft and lie machine

We check the lofts and lies of all our irons and wedges here. There is a device on the other side of the room that does the same thing for putters.

If we need to bend a shaft, which is a fairly regular occurrence, we use a pressurised bending block and insert the club which is placed under 110 PSI.

6: Frequency analyser

This gives us an indication of shaft and flex stiffness. The machine clamps down on the grip section and once you load the club, you lower it down an inch and let go. This makes the club oscillate up and down.

There’s a built-in laser which gives a frequency measurement by tracking how fast or how slow the club is travelling. This gives the most accurate assessment possible of the flexibility in the shaft.

THE NUMBERS…

3,000 Number of shafts stocked

2,000 Grips stocked

750 Iron/wedge clubheads stocked

550 Driver/woods/hybrid clubheads stocked

15 Seconds it takes to regrip a new club

550 Litres of diesel carried on board