Cobra King Supersport-35 is golf’s first fully 3D-printed putter

Last updated:

First fully 3D-printed putter hits the golf market with Cobra King Supersport-35 blade set to revolutionise the way golf equipment is produced.

Cobra Golf have revealed the first of three-planned 3D-printed products for 2021. The new King Supersport-35 putter is the result of a new partnership with printing moguls HP (Hewlett-Packard) and metal injection moulding specialists Parmatech.

RELATED: Full review of the Cobra King Supersport-35 putter

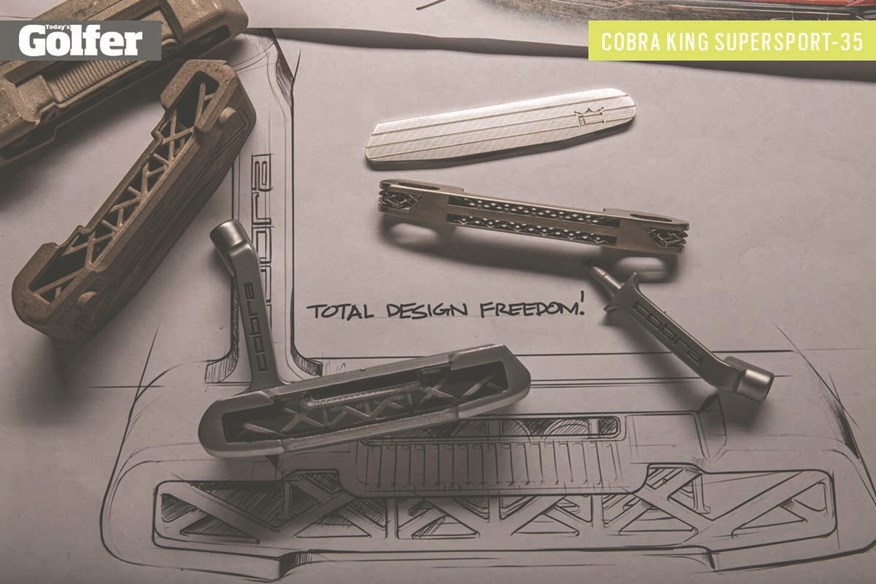

Cobra have been working with HP since early 2019 to see what the company’s Metal Jet 3D printing technology can bring to the golf market. In eight months months the partnership churned out 35 different designs, highlighting the design freedom and production speed benefits over conventional methods.

Barring Ping’s My3D $5,000 printed putter in 2015, this is the first time that 3D printing tech has been fully explored for golf and the first Cobra putter in many years.

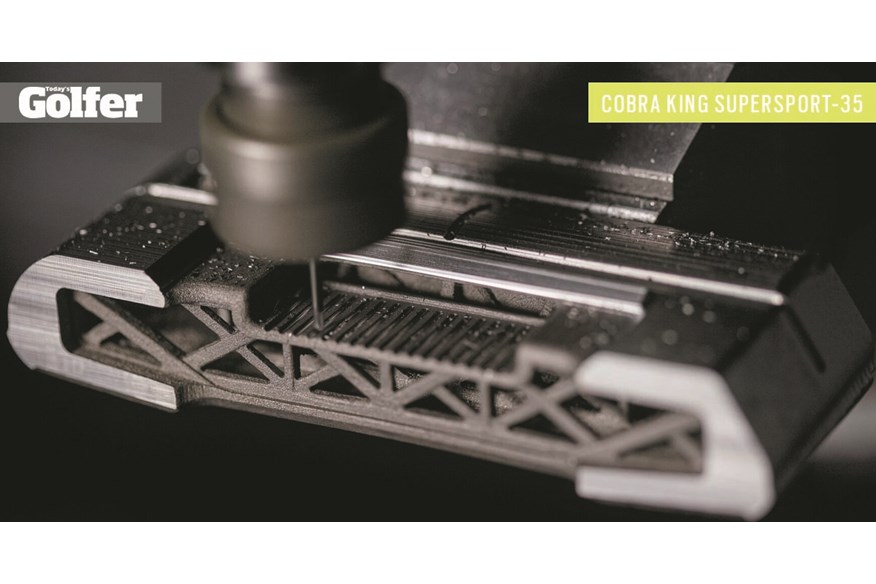

Using this new technology means the King Supersport-35’s parts are produced to a superior quality than casting and forging, providing more consistency from head to head. The putter uses an intricate internal lattice structure that can only be created by 3D printing, giving golfers the highest MOI (most forgiveness) possible from a blade putter without compromising on looks, feel or sound.

RELATED: Everything you need to know about Cobra’s MIM King Tour Iron

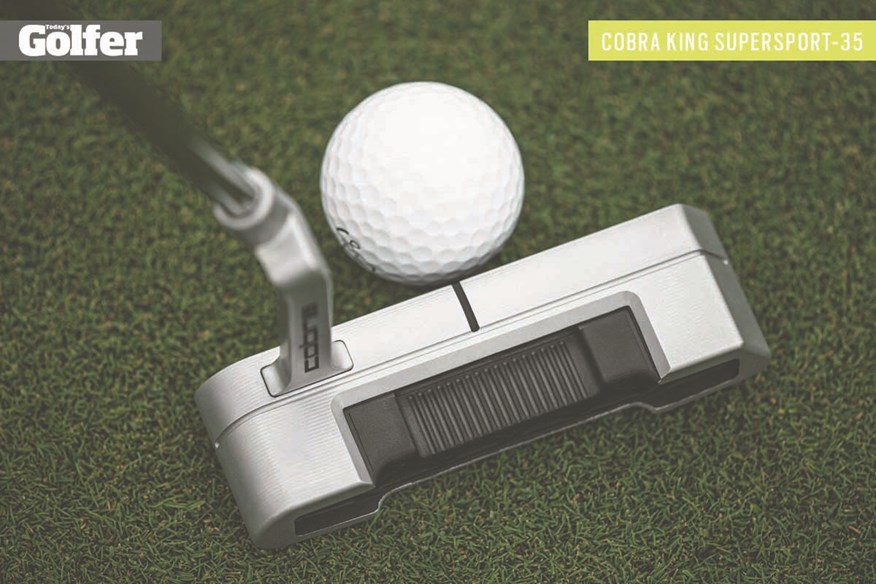

You’ll rarely hear of a highly forgiving and MOI stable blade putter because that’s simply not where they traditionally excel. But with this model Cobra have created a product that their rivals in the golf market can’t compete with right now. The SuperSport-35’s oversized head just exaggerates those forgiveness gains too.

Cobra say that by exploiting the advanced capabilities of Metal Jet printing and thanks to using a 316 stainless steel (which is heat treated at high temperature) they’ve been able to create that unique internal lattice that frees up inefficient weight and pushes the extra mass is pushesd to the perimeter to improve stability.

RELATED: New Odyssey putters see a legend return

Each head is finished on a CNC Mill to ensure precise lines and details, while a a 35° toe hang and a plumbers neck mean it’s a good fit for a slightly arcing putting stroke.

You also get SIK Golf’s descending loft tech. You may have have heard of SIK before, thanks to Bryson DeChambeau’s association with the putter maker, and it’s down to this partnership that the new King Supersport-35 will have exactly the same multi-lofted face technology that’s used by the US Open champ and Cobra staffer.

RELATED: How do Cobra go about dialling in Bryson DeChambeau’s golf clubs?

SIK’s Descending Loft Technology ensures the correct loft is delivered to get the ball running quickly and smoothly even when putts are hit above or below centre. The tech is built into a lightweight aluminium face insert, further helping to repositioned weight and improve MOI even more.

“We strive to deliver high-performance products that help golfers of all levels play their best and enjoy the game, to do that, it’s critical to use the most effective manufacturing processes to design, develop, and achieve optimal results, and we’ve done that with this new putter, ” Jose Miraflor, Cobra’s VP of Marketing, said.

“3D printing is accelerating design innovation, and this breakthrough putter will help usher in a new era for the sporting equipment industry at large.”

This King Supersport-35 putter is available in very limited numbers at £349. Find out more at Cobra Golf.

READ NEXT: Best Putter 2020

-

The new Cobra king Supersport-35 is golf's first fully 3D-printed putter.

The new Cobra king Supersport-35 is golf's first fully 3D-printed putter.

-

The new Cobra king Supersport-35 is golf's first fully 3D-printed putter.

The new Cobra king Supersport-35 is golf's first fully 3D-printed putter.

-

The new Cobra king Supersport-35 is golf's first fully 3D-printed putter.

The new Cobra king Supersport-35 is golf's first fully 3D-printed putter.

-

The new Cobra king Supersport-35 is golf's first fully 3D-printed putter.

The new Cobra king Supersport-35 is golf's first fully 3D-printed putter.

-

The new Cobra king Supersport-35 is golf's first fully 3D-printed putter.

The new Cobra king Supersport-35 is golf's first fully 3D-printed putter.