Inside the Fujikura lab that designs shafts for the world’s best players

Last updated:

We visit the home of Fujikura, to find out how they create golf shafts for the best players in the world.

Most brands working with the best golfers on the planet expect to pay millions of dollars in sponsorship, as tour pro endorsement is the most expensive way to get noticed in golf. Somehow, though, Japanese shaft manufacturer Fujikura buck that trend.

The high-end carbon fiber giant has carved out such an enviable reputation for making the best, most stable shafts available (for major champions, over half the world’s top 10 and swathes of other tour players), the brand is fast becoming recognized as the stock driver shaft out on tour. And somehow they’ve done it without paying a single dime to anyone using the product.

So how do they do it? To find out, we took a trip to the company’s US headquarters in Carlsbad, California. There, we got to take a look inside the lab where they design, prototype and test shafts for the best drivers and best players in the game. Welcome to the shaft lab to the stars.

Who are Fujikura?

Fujikura originally started out in Japan in the 1970s, but in 1994 they decided to set up a US office in Carlsbad, California. The office was formed to create graphite OEM shafts (Original Equipment Manufacturer, so models frequently not made under their own name) for the likes of TaylorMade, Callaway, Titleist and Cobra, who were located locally. Back then, the brand made RCH shafts for Callaway Big Bertha drivers as well as tons of other popular models.

As the popularity of custom fitting has grown in the last decade, Fujukura spotted an opportunity to make shafts across three platforms (good, better and best). So, today their OEM shafts are used within some of the most forgiving drivers from TaylorMade, Ping and Wilson. These models are produced in China, offer solid performance at a reasonable cost for the mass market and each shaft sits within the company’s ‘good’ platform.

However, if you want to explore what premium materials and technology can do for accuracy and consistency, the brand also make after-market models from higher spec aerospace grade materials. These shafts find their way, as custom orders into some of the best low spin drivers available, and are regularly spotted in the hands of the world’s best players. Each of these models sits within the brands ‘best’ platform.

Incredibly Fujikura’s whole US operation is run by just 24 people. The lab designs, prototypes and tests new shaft models, before premium production orders are sent to the company’s Vietnamese and Japanese factories.

How do Fujikura develop new shaft models?

Designing new shaft models is a seriously complex process; the best ideas rarely just spring to mind. Today, the company have their own high-speed camera analysis system (see the enso section below). And a decade’s worth of research data to call upon to test new theories and ideas before making a single prototype.

The company has a design committee made up of leaders from each department within the business. They start by picking the brains of their tour rep, who has worked with the best players in the game for 25 years. Questions range from what’s happening on ranges on tour, to what tour players have requested and whether there are there any up-and-coming products the brand could be losing out to. The sales team throws into the mix what dealers have asked for, and whether the brand is missing anything in the marketplace. The focus then switches to the engineering department for material and process updates.

Once a picture is in place of the whole shaft landscape, the team starts asking where they can make enhancements and advancements. Then, just like baking a cake, new shaft models are started from scratch. They follow a recipe and bring together different carbon fibers (all of which bring different properties to the table) to create the best mixture possible to fulfill an intended use.

Premium shafts are made up of between seven and 23 different pieces of carbon fiber sheet. Each needs to be positioned in various orientations to create the right feel, stability and desired ball flight/spin.

After deciding on the recipe, a detailed spec sheet with the shape, size and material of every piece within the shaft is created. Then the brand’s highly skilled technicians laser-cut each piece and hand-roll them onto a steel central mandrel, before the shaft is baked in an oven to create an ultra-strong graphite tube.

How do Fujikura test new shafts?

Once the brand have hit on what they think is a good idea, they go to the edge of the earth to test and understand what it brings to the party. Prototypes are made on site, a benefit of having an end-to-end production facility based in California. Thanks to curing and drying times, prototypes usually take five days to create.

With prototypes ready the team starts player testing; golfers will hit thousands of shots within the brand’s enso analysis lab. They’ll also head out onto a golf course to get feedback and input into the new design.

Spencer Reynolds, Product and Brand Manager at Fujikura told us: “It would be incorrect and arrogant to say we knew the Ventus shaft was going to take over the world as it has, but the truth is we knew, thanks to the amount of testing we’d done, we had a very good product before it even launched.”

Testing doesn’t stop with players, though; there’s also a fully equipped in-house R&D lab within the Carlsbad HQ. Here, technicians measure and analyze every millimeter of a new design, before new models ever get slated for release. Shafts are also tested to destruction for durability, so they know exactly what any given shaft can take in the real world.

What is enso?

Over a decade ago Fujikura had a burning desire to take shaft understanding to a whole new level. They wanted to create a system that could see what happened at any point along the shaft throughout the entire golf swing. Everything from deflection at impact, to how sections twisted and moved during transition had to be measurable, so engineers could understand how to make better shafts for every level of golfer.

The company partnered with a high-speed 3D motion capture company and between them, they created a 10-camera set-up that typically would be used for the creation of computer-animated films and CGI. Today, there are just three enso systems in the world – one at the Fujikura HQ in Japan, one in the Carlsbad office and one at Ping’s R&D base in Arizona.

The system allows the brand to better understand how shafts perform, and measure the forces various players and speeds put on a shaft at any point during the swing. In short, the brand believe that thanks to this technology, they understand golf shafts better than any competitor.

Because they don’t pay tour players to endorse their products, relying instead upon player discretion to choose the best-performing product for their game, Fujikura can’t name any players who’ve come through the enso lab. But scrolling through their database, the names of multiple men’s and women’s Major winners sit right alongside previous world number ones…

For players who want an extra level of understanding into how shafts work for them, this door is always open.

How do Fujikura get shafts into the top players’ hands without paying them?

It’s all about relationships. Fujikura have a rep at every tour stop. But more often than not they’ll make a special visit for a deep dive into product information if players or reps from tour trucks need to know more. Fujikura reckon they’re better than anyone in the business at building rapport with the tour teams at Callaway, TaylorMade, Titleist and Ping, etc. These are the people working with each brand’s star players day in, day out.

Over the years Fujikura has built a reputation for only bringing new ideas to each tour truck when they’re super confident in their performance. The strategy has led to each OEM having the confidence to willingly showcase Fujikura products to their very best players.

In fact, Fujikura have become so good at researching players during enso test sessions that today they’ll often go to the Callaway, TaylorMade, Ping or Titleist tour trucks offering a list of players who potentially are a good fit for new products, effectively starting an OEM tour rep’s job for them.

Fujikura’s approach means they work with some of the biggest names in golf. But effectively they’re often not getting their hands dirty and working directly with the players on a daily basis. And remember they don’t pay any sponsorship money. It’s a clever strategy for a business that craves tour validation for overall credibility.

Of course, everything revolves around being the best-performing shaft option for any tour pro, which is a massive goal to fulfill. But it’s a testament to the job Fujikura do that their models are regularly the most played driver and wood shafts on tour. They also currently feature in the bags of six of the world’s top 10 players.

How Fujikura make premium after-market shafts

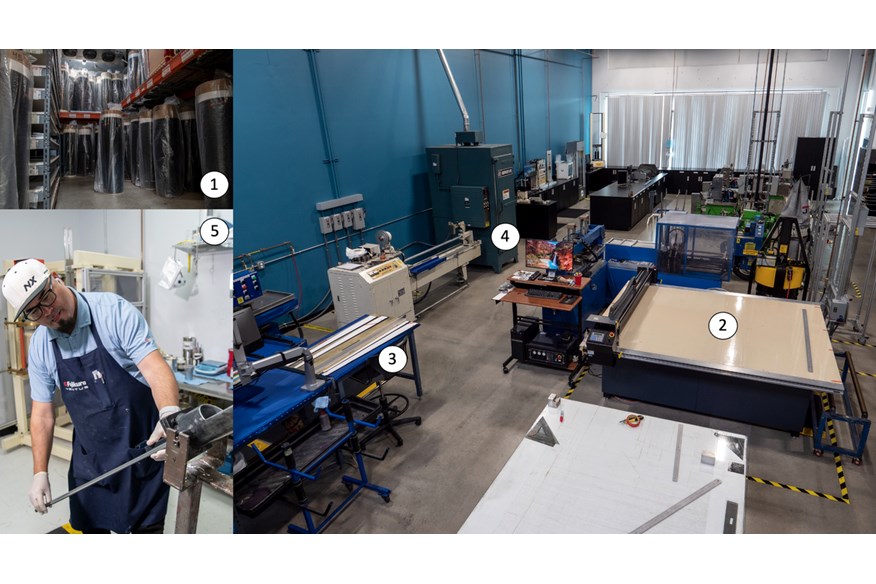

1: Chill out

Carbon fiber is bought in sheets that come rolled around huge cardboard tubes. Each roll is a different type of carbon fiber, so when put together in a myriad of combinations the brand can create any one of their various shaft recipes.

The carbon fiber arrives impregnated with tiny amounts of resin (glue). To keep the material at a stable and consistent temperature all rolls are stored inside a chiller. Rolls are individually brought out of the chiller to the cutting table.

2: Laser cut

Fujikura’s engineers create extremely complex cutting sheets for each of their individual shaft models, weights and flexes. The dimensions and pattern for each part (remember every shaft can range from seven-23 different pieces) is pre-programmed into a laser cutter. The computer-controlled cutter consistently and accurately cuts the pieces for each individual shaft design.

With all of the pieces labeled and bundled together the jigsaw puzzle of pieces is handed over to a highly skilled graphite shaft rolling technician.

3: Hand rolled

All the pieces of each shaft need to be hand positioned and rolled around a precisely-shaped metal core (a mandrel). Layers are built up one at a time. Once the technician has correctly positioned each piece a rolling machine wraps the carbon fiber around the mandrel tightly.

To ensure golfers get the intended performance differences between shaft models, the tolerances for positioning each piece are minuscule. It takes months to learn to roll some of the brand’s most complex shaft models. Once all pieces are in place, the shaft and mandrel are shrink-wrapped under pressure. The process squashes out air and ensures a good fusion between each layer and the resin inside.

4: Baked

Fujikura weren’t too keen to share specific details about how long shafts are baked for, and at what temperatures they cure. But, every shaft produced spends time passing through an industrial oven to set. Once the shaft has cooled the steel mandrel from the center is withdrawn, leaving a blank carbon fiber tube for adornment.

5: Painted

To ensure a perfectly even coat each shaft is pulled through a specially prepared paint-laden cloth. It takes years of practice and patience to draw the entire length of a shaft through the paint in one consistent movement. The brand experiment with all sorts of paint colors and combinations for special one-off models.

Once the paint dries, logos and decals are silk screen printed on top. From there, shafts can go directly to the test bay, golf course or get boxed up and shipped out.

READ NEXT

– Which Fujikura driver shaft suits you?

BECOME A TODAY’S GOLFER MEMBER: Unlimited access to premium content and exclusive rewards!

-

A graphic to show the different parts of the Fujikura shaft production process

A graphic to show the different parts of the Fujikura shaft production process

-

An image showing the inside of the paint room at the Fujikura shaft lab

An image showing the inside of the paint room at the Fujikura shaft lab

-

An image showing the inside of the Fujikura shaft production lab

An image showing the inside of the Fujikura shaft production lab

-

An images showing what happens inside the Fujikura enso shaft testing lab

An images showing what happens inside the Fujikura enso shaft testing lab

-

A collage of images to show what Fujikura do

A collage of images to show what Fujikura do

-

An image showing a Fujikura technician rolling graphite shafts

An image showing a Fujikura technician rolling graphite shafts

-

An image showing all the premium shafts that Fujikura make

An image showing all the premium shafts that Fujikura make