Cobra King Supersport-35 3D printed putter Review

Last updated:

-

At a glance

- TG Rating

- Owner Rating

What we say...

The Cobra King Supersport-35 is the first fully 3D printed putter to hit the market. Cobra say 3D printing holds the keys to revolutionising golf equipment as we know it…this is how.

3D printing as a technology has transformed how parts are made for everything from heart valves to homemade guns. But, with the exception of Ping’s My3D $5,000 printed putter experiment back in 2015, the tech’s never really been fully explored in golf.

RELATED: Cobra’s RADSPEED 2021 range unveiled

All that is set to change thanks to a brand new partnership between Cobra Golf, printing moguls HP (Hewlett-Packard) and metal injection moulding specialists Parmatech.

RELATED: Cobra’s Metal Injection Moulded King Tour Iron

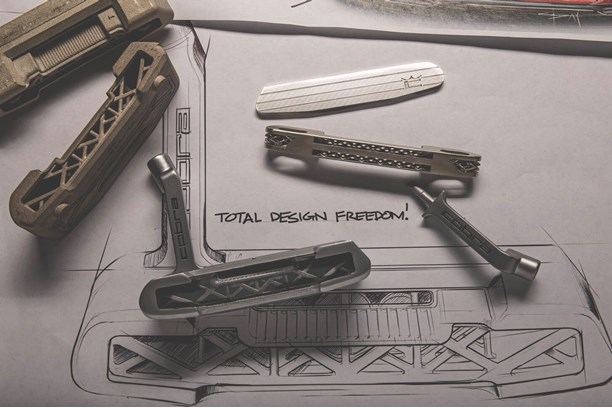

Since early 2019 Cobra and HP have been exploring what advantages HP’s Metal Jet 3D printing technology can bring to golf. Over eight months the partnership has churned out 35 different designs, all of which showcase how the tech gives more design freedom and increases the speed of product innovation over conventional methods.

With 3D printing likely to change product development forever, the pair have agreed a multi-year agreement and they’re planing to introduce three new 3D printed products in 2021.

RELATED: Best Putter 2020

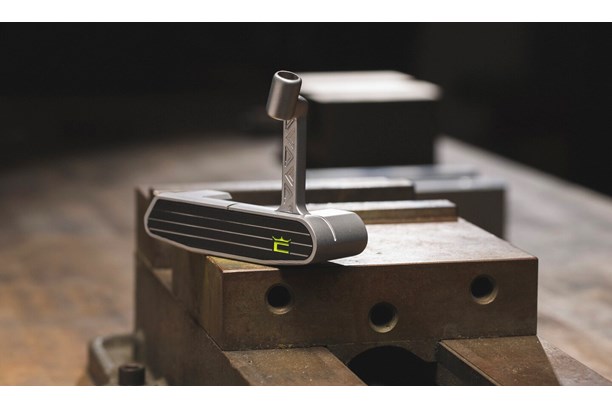

The first is ready to go, and Cobra have chosen to show the benefits 3D printing brings to golf clubs within a brand new King Supersport-35 blade putter. Cobra might not have made putters for a while but they swear that, thanks to an intricate internal lattice structure that can only be created by 3D printing, golfers get the highest MOI (so most forgiving) possible from a blade putter. Here’s how they do it…

What are the benefits of 3D printing a golf club?

Well there’s actually quite a few. HP’s Metal Jet 3D printing means parts are produced to a superior quality than casting and forging, which means less hand finishing by less people which improves consistency from head to head. But that’s just scraping the surface of the potential benefits and improvements.

Of course, there’s a significant gain in the time it takes to go from prototyping to bringing the product to market as well. Unlike most golf brands, R&D departments who use rapid 3D printed prototypes will actually produce stock heads on exactly the same machinery that creates the proto’s.

But the biggest breakthrough is what 3D printing can deliver is in terms of performance gains. And by that we mean a better performing product thanks to the ability to create a strong, stable lattice design that lets engineers remove weight from inefficient areas. But even with mass removed, golfers get the same familiar sound, feel and looks that we’re used too. It’s just like when TaylorMade’s original Pittsburgh Persimmon metal driver replaced wooden woods forever.

WATCH: Bryson DeChambeau on the Cobra King Supersport-35 putter

RELATED: How to choose your perfect putter alignment aid

So how is the Cobra King Supersport-35 putter better?

Absolutely nobody talks about the forgiveness or MOI stability of blade putters. Why? Well because they’re not actually that stable at all. Even a toe and heel weighted Ping Anser style blade will never shout about forgiveness and stability because that’s not where they excel.

What Cobra have done here is identify an area where 3D printing tech can really make a difference, and they’ve gone straight for the throat with the Supersport-35, creating a product others can’t compete right now. An oversized head just exaggerates those forgiveness gains too.

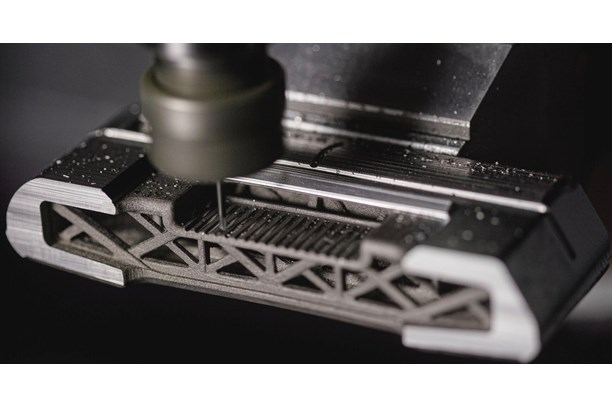

Cobra say by exploiting the advanced capabilities of Metal Jet printing and thanks to using a 316 stainless steel (which is heat treated at high temperature) they’ve been able to create a unique internal lattice that frees up inefficient weight. That extra mass is pushed to the perimeter (without the need for fixed weights) to improve stability. But there’s another gain, too, and that’s how the material and lattice design fine tunes feel. This sort of design just isn’t possible when forging or casting.

To ensure precise lines and details each head is finished on a CNC Mill. Cobra say the King Supersport-35 has a 35° toe hang and a plumber neck, which means it’s a good fit for a slightly arcing putting stroke.

RELATED: Robot Tested – Which golf ball is right for you?

You also get SIK Golf’s descending loft tech

Bryson DeChambeau has had a massive impact on the game in 2020, and it’s thanks to his association with putter maker SIK Golf that Cobra’s new King Supersport-35 will have exactly the same multi-lofted face technology that’s used by the US Open champ.

SIK’s Descending Loft Technology (DLT) means the face has four different lofts (1°, 2°, 3°, 4°), as SIK say putter shaft angle at impact rarely matches what it was at address. It means no matter whether putts are hit above or below centre the correct loft is delivered to get putts running quickly and smoothly.

And because the tech’s built into a lightweight aluminium face insert extra weight’s removed from the front of the putter and repositioned to further improve MOI.

WATCH: How Cobra and HP create the King Supersport-35 putter

Where will Cobra go next with 3D printing?

It’s really early days for this new tech but from how Cobra have pitched it, 3D printing could be a big breakthrough for golf. Obviously there will be limitations, but if Cobra’s first foray into the arena is anything to go by, it looks there’s likely to be benefits to golfers anywhere inefficient mass can be freed up by a lightweight lattice type structure.

Cobra have made no mention yet about the other two 3D-printed products they’re launching in 2021, but from where we’re standing it’s not beyond the realms of possibility to think there could be gains in iron and wedge head structures and plenty more putter designs.

This first 3D printed King Supersport-35 putter is available in very limited numbers at £349 a pop. We’re just trying to decide if it will be a collector’s item of the future. Find out more at Cobra Golf.

RELATED: How do Cobra dial in Bryson DeChambeau’s golf clubs?

Cobra’s VP of Marketing Jose Miraflor on the King Supersport-35 putter

“We strive to deliver high-performance products that help golfers of all levels play their best and enjoy the game, to do that, it’s critical to use the most effective manufacturing processes to design, develop, and achieve optimal results, and we’ve done that with this new putter.

“To continue innovating and transforming the way equipment is manufactured, we worked with HP and Parmatech to take advantage of the benefits of Metal Jet technology. During the development of the King Supersport-35 putter, we saw immediate benefits from the process, including design freedom, rapid design iteration, and high-quality parts that meet our economic demands.

“3D printing is accelerating design innovation, and this breakthrough putter will help usher in a new era for the sporting equipment industry at large.”

Global Head of HP Metal Jet at HP Inc, Uday Yadati on the Cobra/HP partnership

“The power of personalization enabled by 3D printing delivers completely reimagined consumer products and experiences. This first of its kind putter is a shining example of the disruptive design and production capabilities of HP Metal Jet 3D printing technology.

“Cobra’s commitment to innovation and competitive excellence combined with the technical expertise and leadership from Parmatech has led to a breakthrough design win for golf fans around the world.”

READ NEXT: What is putter toe hang? And why is it important?

Review written by: Simon Daddow

Job title: Today’s Golfer – Equipment Editor